Panorama of China's refractory materials industry in 2023

Dec 05, 2023China's refractory materials industry implements a regulatory system that combines competent authorities and industry associations and self-regulatory organizations. Among them, the industry competent department is the Ministry of Industry and Information Technology, which is responsible for macro management functions, supervises and manages the refractory industry, and formulates industrial development policies, regulations, etc.; the industry self-regulatory organization is mainly the China Refractory Industry Association, whose main responsibility is to assist the government in implementing industry management and It plays a coordinating role, safeguards the overall interests of the industry and the legitimate rights and interests of enterprises within the industry, and guides the healthy development of the industry. In recent years, relevant national departments have provided policy guidance and regulatory requirements in eliminating backward production capacity and raising the entry threshold for the refractory materials industry, thereby promoting an upward trend in the concentration of the refractory materials industry.

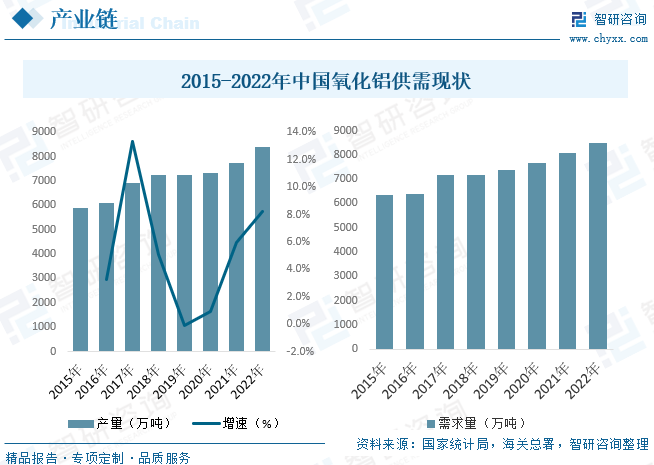

In recent years, as China's demand has driven the rapid growth of global alumina demand, international aluminum giants such as Rio Tinto Group, Alcoa, and Rusal have formed strategic alliances, and alumina pricing methods have gradually moved towards indexation. The value of aluminum resources is gradually reflected. The distribution of alumina production capacity in my country is resource-oriented. Alumina production capacity is mainly concentrated in Shandong, Henan, Shanxi, Guangxi, Guizhou and other places. The alumina production capacity of these five provinces accounts for nearly 95% of the country's total alumina production capacity. According to statistics, the output of my country's alumina industry in 2022 will be 83.862 million tons, and the demand will be 84.845 million tons. Relying on the advantages of raw materials such as bauxite and magnesite, my country has been the largest producer of refractory materials in the world for many years. According to statistics, from 2014 to 2017, in the context of supply-side reform, downstream steel and other industries continued to reduce overcapacity and superimposed refractory materials.

In recent years, as China's demand has driven the rapid growth of global alumina demand, international aluminum giants such as Rio Tinto Group, Alcoa, and Rusal have formed strategic alliances, and alumina pricing methods have gradually moved towards indexation. The value of aluminum resources is gradually reflected. The distribution of alumina production capacity in my country is resource-oriented. Alumina production capacity is mainly concentrated in Shandong, Henan, Shanxi, Guangxi, Guizhou and other places. The alumina production capacity of these five provinces accounts for nearly 95% of the country's total alumina production capacity. According to statistics, the output of my country's alumina industry in 2022 will be 83.862 million tons, and the demand will be 84.845 million tons. Relying on the advantages of raw materials such as bauxite and magnesite, my country has been the largest producer of refractory materials in the world for many years. According to statistics, from 2014 to 2017, in the context of supply-side reform, downstream steel and other industries continued to reduce overcapacity and superimposed refractory materials.

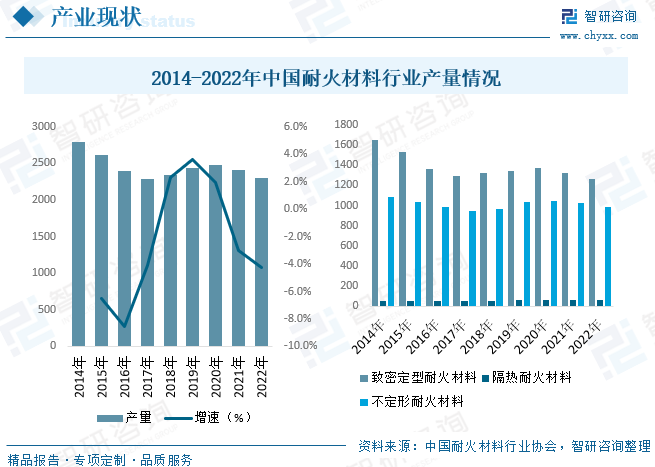

The extended life of materials has led to a decrease in unit consumption, and the demand for refractory materials has continued to adjust. The output has dropped from 29.2825 million tons to 22.9254 million tons. From 2018 to 2020, benefiting from the development of the downstream industry, output stabilized and rebounded slightly. As of 2021, the output of refractory materials has reached 24.0267 million tons, a year-on-year decrease of 3.04%; as of 2022, my country's refractory material output has reached 23.0099 million tons, a year-on-year decrease of 4.23%. After entering the 21st century, with the deepening of reform and opening up, our country has ushered in a great development of the metallurgical industry.

The extended life of materials has led to a decrease in unit consumption, and the demand for refractory materials has continued to adjust. The output has dropped from 29.2825 million tons to 22.9254 million tons. From 2018 to 2020, benefiting from the development of the downstream industry, output stabilized and rebounded slightly. As of 2021, the output of refractory materials has reached 24.0267 million tons, a year-on-year decrease of 3.04%; as of 2022, my country's refractory material output has reached 23.0099 million tons, a year-on-year decrease of 4.23%. After entering the 21st century, with the deepening of reform and opening up, our country has ushered in a great development of the metallurgical industry.

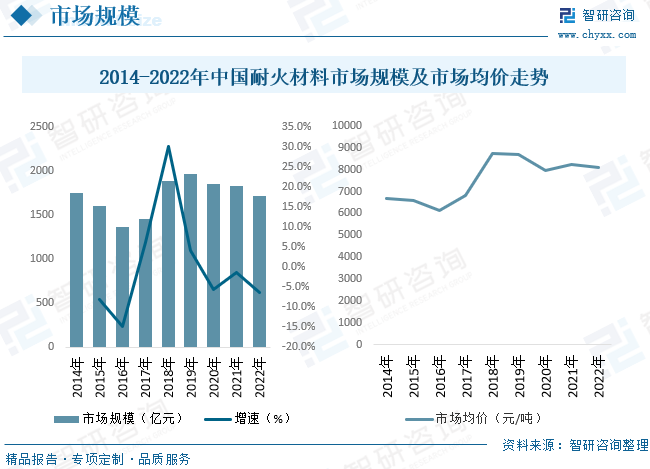

Especially after 2003, driven by the rapid development of steel, building materials, petrochemical and other industries, batches of private and joint venture refractory materials Enterprises stepped onto the stage, and the refractory materials industry developed rapidly. Since 2013, with the advancement of my country's economic transformation and development and industrial policies such as energy conservation, emission reduction, and compression of backward production capacity, the growth rate of high-temperature industries such as steel, nonferrous metals, and building materials has slowed down, which has also indirectly guided the development direction of refractory materials. In recent years, In the coming years, the overall market size of my country's refractory materials industry will grow. As of 2022, the market size will be approximately 171.798 billion yuan.

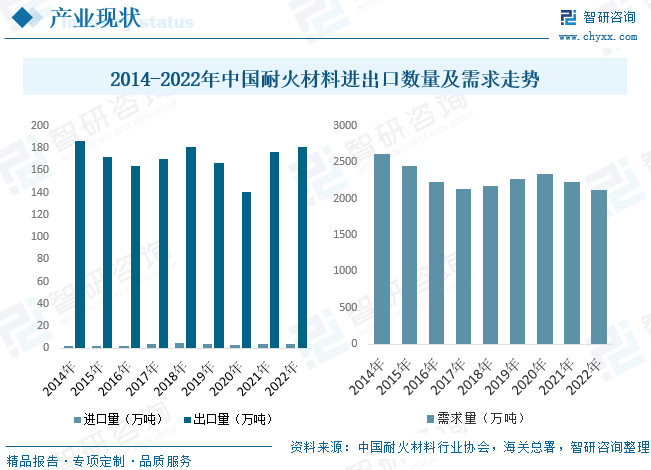

The influence of my country's refractory industry in the world's refractory industry continues to increase. At present, our country has become the manufacturing center, consumption center and trade center of refractory materials in the world. The competitiveness of my country's refractory products in the international market is gradually increasing, with markets covering about 150 countries and regions including Southeast Asia, North America, South America, the European Union, and Russia. Judging from the export quantity of my country's refractory products from 2014 to 2022, although the export quantity of my country's refractory products has not changed much, the export price has increased rapidly, indicating that the export product structure is optimizing. In the past few years, the main downstream industries of refractory materials have continued to develop at a rapid pace, which will promote the gradual increase in demand for refractory materials.

So far, China's steel, cement, non-ferrous metal smelting, glass and ceramics production ranks first in the world. In the next few years, domestic steel companies' demand for refractory materials will continue to increase. The refractory material industry is a fully competitive industry and is affected by the geographical division of the downstream steel industry and main raw materials. It has a certain regional nature. my country's main refractory material production enterprises are located in Liaoning, Henan, Shandong, Shanxi, Jiangsu and Zhejiang. There are many refractory companies in my country. There are 2,000 refractory products and raw material companies included in the statistics of the Refractory Industry Association alone. In addition, there are still a large number of small and medium-sized refractory companies that are not included in the statistics. my country's refractory materials industry is characterized by a high degree of marketization, low industry concentration, and small and dispersed enterprises. The phenomenon of product homogeneity among refractory material companies is quite serious. What affects corporate profitability is more the gap in corporate equipment levels. However, with the improvement of industry policies and entry thresholds, industry concentration and the market share of leading companies will accelerate in the future.

During the 14th Five-Year Plan, the development of refractory materials will take on new characteristics. The basis is to improve product quality and application level, and the focus is to add or strengthen new connotations, namely energy conservation, environmental protection and low carbon. The basic direction of the development of refractory materials science and technology is to take independent innovation as the basic starting point, follow the integrated path of scientific design and application of refractory materials, refinement and green production and application, consumption reduction and resource conservation, and promote research and development to re- Go to a new level. Among them, the innovation direction of refractory materials for the cement industry is chromium-free and energy-saving.

The overall development level of my country's refractory industry is still far from advanced green. Green refractory materials have attracted the attention of refractory materials and related industries. Relevant government departments and industry associations have also formulated corresponding policies and measures to encourage and promote the greening of refractory materials. Strengthening energy conservation and emission reduction and developing green and low-carbon refractory products are fundamental requirements of the global green economic strategy for the refractory industry. Further promoting technological innovation, product structure adjustment and application technology improvement in the refractory materials industry, and vigorously developing new green refractory products that are long-lasting, energy-saving, and environmentally friendly have become a major trend in the current development of the refractory materials industry.

Tags :