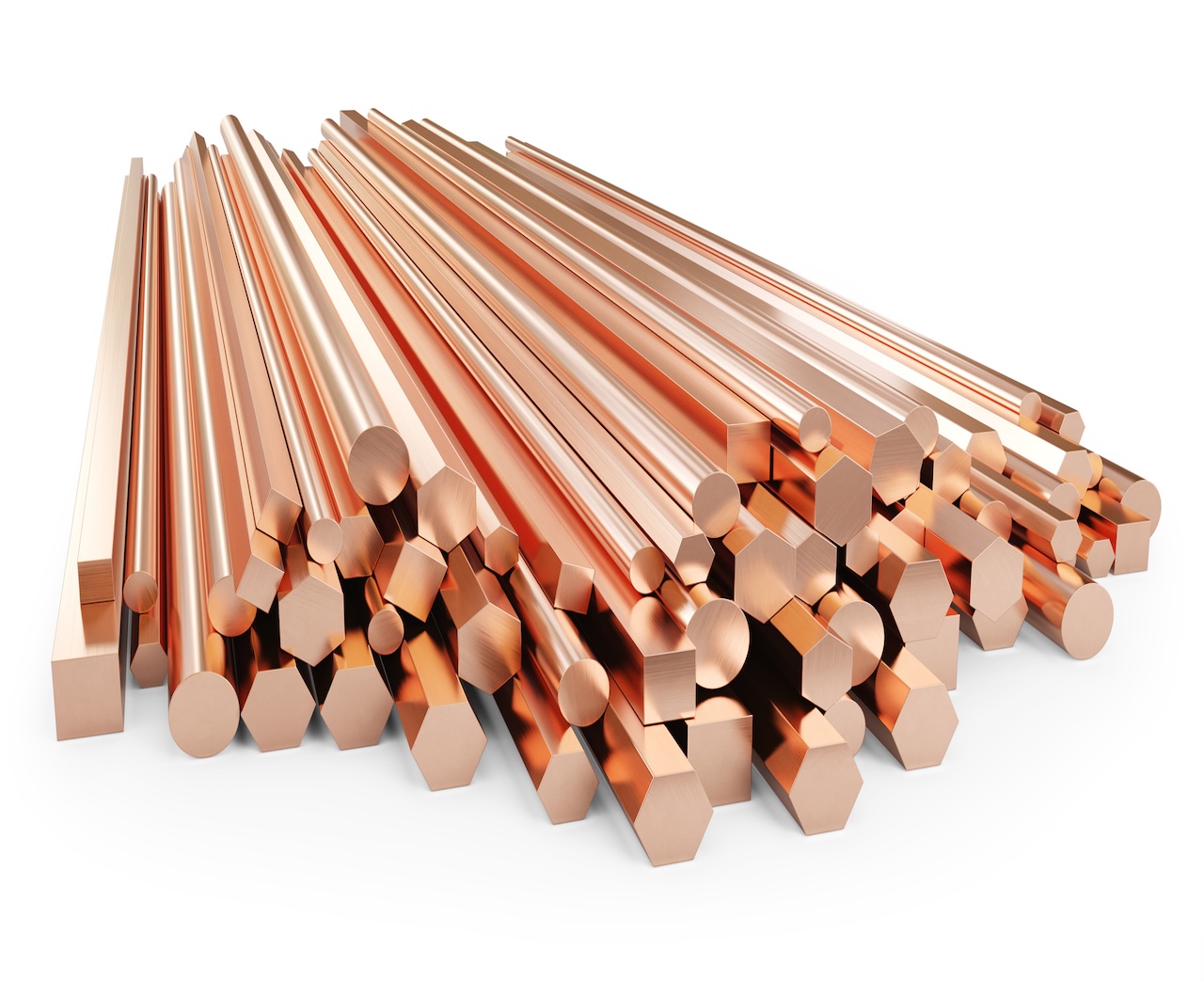

Enhancing Welding Performance with Chromium Zirconium Copper Bars

Jun 17, 2025In the welding and cutting industry, materials are constantly pushed to their limits by heat, friction, and electrical loads. Chromium Zirconium Copper (CuCrZr) has emerged as a superior alloy choice, offering the perfect balance of high conductivity, exceptional wear resistance, and thermal stability. Among its most common forms, the Chromium Zirconium Copper bar is widely used in high-demand welding components such as resistance welding electrode caps and contact tips for gas shielded welding.

Chromium Zirconium Copper, often referred to as CuCrZr or C18150, is a high-performance copper alloy that contains a small amount of chromium and zirconium (typically 0.5–1.2%). Through solution strengthening and precipitation hardening, this alloy delivers high hardness and excellent heat resistance, without significantly compromising electrical conductivity—making it ideal for both electrical and mechanical applications in welding.

Electrode caps are subjected to extreme pressure and high current during resistance spot welding. CuCrZr bars are machined into electrode caps for materials like galvanized steel, stainless steel, and aluminum sheets. Thanks to its superior hardness and high softening temperature (over 500°C), Chromium Zirconium Copper maintains its shape and contact integrity over extended welding cycles.

Benefits include:

Long service life compared to pure copper electrodes

Better heat dissipation, reducing spatter and wear

Maintains high contact force under heat and pressure

In MIG/MAG welding, the contact tip is responsible for transferring current to the welding wire while withstanding high thermal stress. CuCrZr contact tips manufactured from precision copper bars resist deformation and erosion, resulting in more stable arcs, less wire sticking, and cleaner welds.

Key advantages:

Excellent electrical conductivity (above 75% IACS)

Strong resistance to tip melting and erosion

Extended tip life in automated or robotic welding systems

High Electrical and Thermal Conductivity

Keeps the welding process stable and energy-efficient.

Exceptional Hardness and Wear Resistance

Reduces downtime and maintenance costs in production lines.

Heat Softening Resistance

Ideal for continuous and high-cycle welding tasks.

Machinability

Easily processed into various custom shapes like caps, rods, tips, and holders.

At Dysen Industrial, we supply high-quality Chromium Zirconium Copper bars in various dimensions, tailored for manufacturers of welding parts. Whether you’re producing electrode caps for automotive spot welding or contact tips for robotic MIG torches, our CuCrZr material guarantees consistency and performance.