Unlocking the Versatility of High Precision Brass Strip in Modern Manufacturing

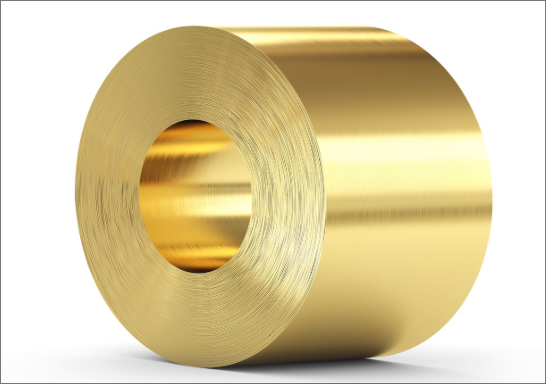

Jun 17, 2025In today’s fast-paced industrial world, high precision brass strip plays a critical role in manufacturing components that demand tight tolerances, excellent conductivity, and superior surface quality. As industries move toward miniaturization and high-performance assemblies, precision brass strips offer an ideal solution that bridges reliability, processability, and aesthetics.

High precision brass strip is a type of rolled copper-zinc alloy material, typically produced through advanced cold rolling and slitting techniques. These strips are characterized by their consistent thickness, smooth surfaces, and excellent mechanical properties. Materials like H62, C2680, and C2600 are commonly used grades, tailored for different strength and conductivity requirements.

At Dysen Industrial, we specialize in supplying high-quality brass strips with controlled width, thickness (as low as 0.05 mm), and surface treatments—making them ideal for high-end industrial and electronic use.

1. Excellent Dimensional Tolerance

Precision brass strips are produced with strict tolerance control, ensuring uniformity in mass production processes. This is crucial for stamping parts, connector pins, and flexible components.

2. High Electrical Conductivity

Brass strips retain good electrical and thermal conductivity, making them suitable for terminals, connectors, battery tabs, and heat-dissipating parts.

3. Superior Workability

Thanks to their ductility and consistent mechanical properties, these strips can undergo multiple forming processes such as bending, stamping, punching, and deep drawing without cracking.

4. Corrosion Resistance and Surface Quality

The surface of high precision brass strip can be bright annealed or coated depending on application needs. Its resistance to oxidation and discoloration ensures longevity, especially in electronics and decorative parts.

The demand for high precision brass strips spans multiple sectors:

Electronics: Used in terminals, lead frames, connectors, and precision stamped components for smartphones, automotive sensors, and IoT devices.

Automotive: Applied in fuse clips, connectors, and switch components due to their stability and conductivity under high temperatures.

Telecommunications: Ideal for RF shielding, grounding plates, and flexible contact points.

Precision Engineering: Used in gear components, watch parts, and high-frequency mechanical elements where accuracy is critical.

Decorative Applications: High surface finish makes brass strips suitable for badges, emblems, and trim parts.

At Dysen Industrial, we provide high precision brass strip solutions tailored to your exact specifications. With advanced slitting, surface treatment, and quality inspection systems, we ensure that every coil or roll meets international quality standards such as ASTM, JIS, and EN.

Whether you're a connector manufacturer, automotive supplier, or electronic component producer, our brass strips can improve your processing efficiency and product consistency.

Tags :