How to calculate refractory bricks for rotary kiln?

Feb 28, 20241 Method of equipping rotary kiln with refractory bricks

The previous method of using one kiln type and one brick type with refractory bricks is no longer available, because the traditional method of using one kiln brick type is used. On the surface, it seems that the center line of the bricks can coincide with the center line of the kiln, but in fact, the kiln is not always absolutely round. In addition, after being used for a period of time, the roundness becomes worse. In this way, it is difficult to guarantee the kiln performance with a single type of refractory bricks. The quality of masonry.

Instead, two different brick types are now used. One has a radius of curvature greater than the half radius of the rotary kiln, and the other has a radius of curvature smaller than the radius of curvature of the rotary kiln. The two types of bricks are matched so that the center line swings left and right near the center point of the kiln, approximately approaching the center point. This brick matching method is reasonable and easy to adjust. According to the size of the kiln, two different brick types are selected for masonry construction.

2 Introduction to two standard brick types

At present, most of the cement rotary kiln refractory bricks used in our country adopt two standards: VDZ standard (German standard) and ISO standard (international standard). The VDZ standard brick type is smaller and is suitable for alkaline bricks with large expansion, such as magnesia-aluminum tip. Fine stone bricks, magnesia-iron fine stone bricks and direct bonded magnesia-chromium bricks, etc. The characteristic of this brick is that its isosceles trapezoidal cross-section centerline width is a fixed length of 71.5mm. Taking the 5000t/d kiln as an example, the effective inner diameter of the kiln barrel is 4.8m, and B622 bricks are generally used in conjunction with B322 bricks. The "6" and "3" represent that the brick is used in a kiln with a diameter of 6m and 3m respectively, and the "22" behind it represents that the brick thickness is 220mm. so. For a kiln with a diameter of 4.8m, the ratio of B622 and B322 bricks is 126:75 through the brick matching table (regardless of the thickness of the fire mud and sealing bricks).

The ISO standard brick type is larger and is suitable for acid bricks with small expansion or even negative expansion, such as anti-flaking high alumina bricks, silica molybdenum bricks, etc. The characteristic of this kind of brick is that the width of the large end of the wedge-shaped surface is fixed length, which is 103mm. Taking the 5000d/t kiln type as an example, the effective inner diameter of the kiln barrel is 4.8m. Generally, A622 bricks are used in conjunction with A322 bricks ( There are also those that use A622 and A422 bricks, and their numbers have the same meaning as VDZ standard bricks). For a kiln with a diameter of 4.8m, the ratio of A622 and A322 bricks. The brick matching manual table is 109:38 (regardless of fire clay thickness and sealing bricks).

3. Establishment of theoretical mathematical model

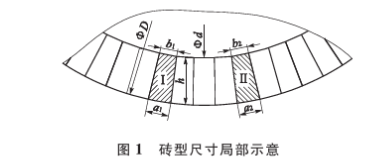

Assume that the inner diameter of the kiln barrel is D, the effective inner diameter of the kiln after laying refractory bricks is d, and the height of the refractory bricks is h. Assuming that it is built with two types of refractory bricks, type I and type II, the width of the large end of the wedge surface of type I bricks is a1, the width of the small head is b1; the width of the large head of the wedge surface of type II brick is

a2, small head width size b2. The height is h, see Figure 1.

Assume that the theoretical matching ratio of type I and type II bricks is x:y, establish a mathematical model, and make the following approximation:

l) The sum of the width dimensions of the large ends of the two kinds of brick square surfaces is equal to the circumference of the inner diameter of the kiln barrel;

2) The sum of the small head width dimensions of the two brick-shaped surfaces is equal to the perimeter of the effective inner diameter of the kiln after the bricks are laid;

With the above assumptions, we can establish the following system of equations:

a1*x+a2*y=π*D

b1*x+b2*y=π*d

Obtained from the above system of equations:

x=value1

y=value2

Among them: d=D-2*h

4 Use Excel to calculate brick distribution

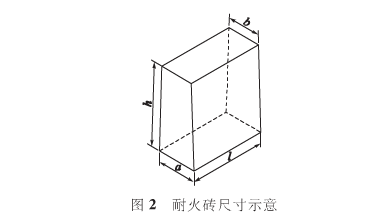

Taking a 5000t/d kiln with an inner diameter of 4800mm and B622 and B322 bricks as an example, the two types of brick rulers are shown in Figure 2 and Table 1.

Table 1 Brick size table

brick type

A B h l

B622

74

69 220 198

B322

76.5

66.5

220 198

After data input is completed, enter in cell C6: "=B6-2*$DS2", enter in cell D6: "=3.14*( B6*$CS3-C6*$B$3)/(SBS2* SCS3-$ BS3* SCS2), enter in cell E6: "=3.14*(B6*$C$2-C6*SBS2)/($B$3*$CS2-SCS3* $B$2)". It will be displayed as shown in Figure 3 The calculation result is that the ratio of B622:B322 bricks is 126:75.

This calculation method can not only obtain the brick distribution data for various kiln types corresponding to different brick types, but also calculate the brick distribution data for different sized parts such as tertiary air ducts, decomposition furnaces and hot air ducts.

If you need this table, you can add WeChat 15378762417. Note: Rotary kiln refractory brick matching brick calculation table

5 Use mathematical formulas to calculate the amount of refractory bricks

Taking the diameter of the rotary kiln cylinder as D4.8m, the length of the construction and maintenance kiln as L20m, and the thickness of the refractory bricks as masonry as H220mm, the amount of magnesia spinel bricks used is calculated as an example:

Tonnage calculation:

M=V*p

V=S*L

S=S1-S2

S1=π*r12

S2=π*r22

r1=D/2

r2=(D-H)/2

M=((π*r12-π*r22)*L)*p

Note: p——is the density of mafic spinel refractory bricks, in g/cm3, calculated as 2.98, and the value of high alumina bricks is 2.2-2.75, which is determined according to the density of the manufacturer's product;

M——is the tonnage of the rotary kiln, in tons;

Convert D, L units to mm, millimeters

M=3.14*((4800/2)2-(4800-220)2)*20000*2.98=53710328/1000000=53.7 tons

Since the units need to be converted, the calculated value divided by 1,000,000 is the tonnage.

6 things to note

The above data are purely theoretical calculations, and there are some differences from the actual brick configuration. No matter what type of kiln, there are always slightly more bricks with a large curvature radius than the theoretical calculation. This is because: the kiln cylinder cannot be an ideal circle, and the use of After a period of time, the deformation and distortion become more serious, the roundness is worse, and the radius of curvature of the deformed part often becomes larger. Through comparison of brick distribution in several 5000t/d production lines, the actual ratio of B622:B322 bricks is about 134:67, which can be Simplified to a ratio of 2:1. In addition, this calculation does not consider the joint sealing bricks and the use of refractory mud. In fact, each ring requires about 2~3 joint bricks and a small amount of refractory mud. These are used in the actual brick matching plan. due consideration should also be given.