High-purity copper refers to copper materials with a purity of 99.9999% (6N) or above, High-purity copper targets, as core materials for chip manufacturing, directly affect the performance of integrated circuits in the 7nm to 3nm process.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working days1、Product Types:

Profiles: Foil, wire, targets (rods, ingots, plates)

2、Characteristics

Electrical and Thermal Conductivity: Low resistivity and high thermal conductivity make it suitable for the production of high-performance conductive/heat dissipating films.

Ultra-High Purity: Low impurity content ensures the reliability and stability of electronic devices.

Dense and Uniform: Dense microstructure and fine and uniform grains ensure uniform sputtering film formation.

Oxidation Corrosion: A dense oxide film forms on the surface, extending the target's service life. (Note: Storage in an inert atmosphere is required to prevent excessive oxidation.)

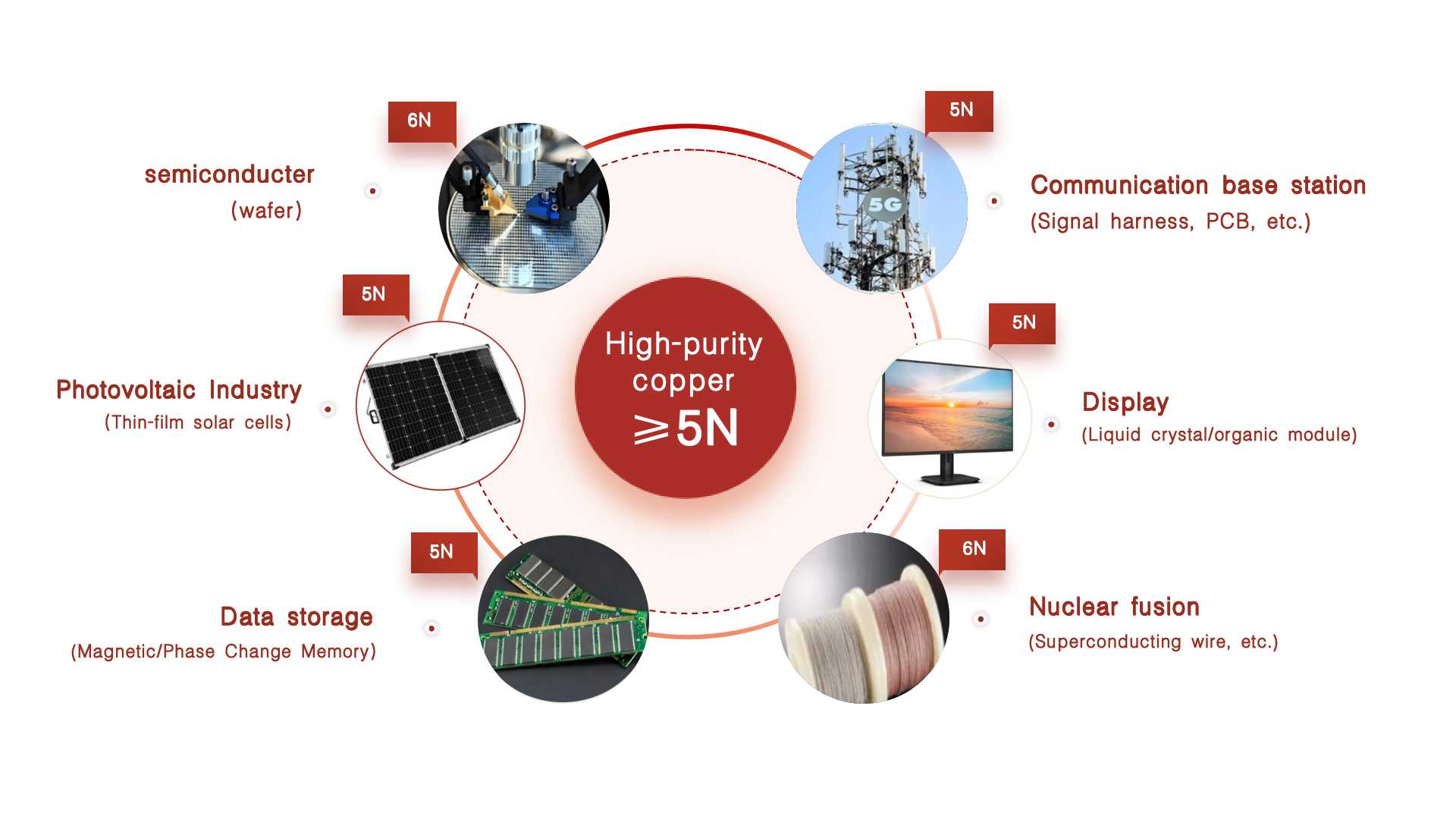

3、Applications

Electronic Information Industry

Integrated Circuit Lead Frames: Require high electrical conductivity, high thermal conductivity, and high strength to ensure chip heat dissipation and signal transmission quality.

High-End Wire: Used in high-frequency coaxial cables, ultra-fine enameled wire, audio and video signal cables, etc., with extremely low transmission loss and high fidelity.

Coating Target: Used in semiconductor chip manufacturing to deposit copper interconnects on silicon wafers through methods such as sputtering.

Ultra-High Vacuum

Used in vacuum chamber components for particle accelerators, synchrotron radiation devices, and nuclear fusion experimental facilities (such as ITER). Due to its extremely low gas content and outgassing rate, it can maintain a high vacuum environment within the devices.

Aerospace and Military Industry

Used in the manufacture of high-reliability, high-precision conductive components, waveguides, and rocket engine cooling channels.

New Energy Industry

Used in high-performance electric vehicle drive motor rotor bars, reducing resistance and improving energy efficiency and power density.

Tags :