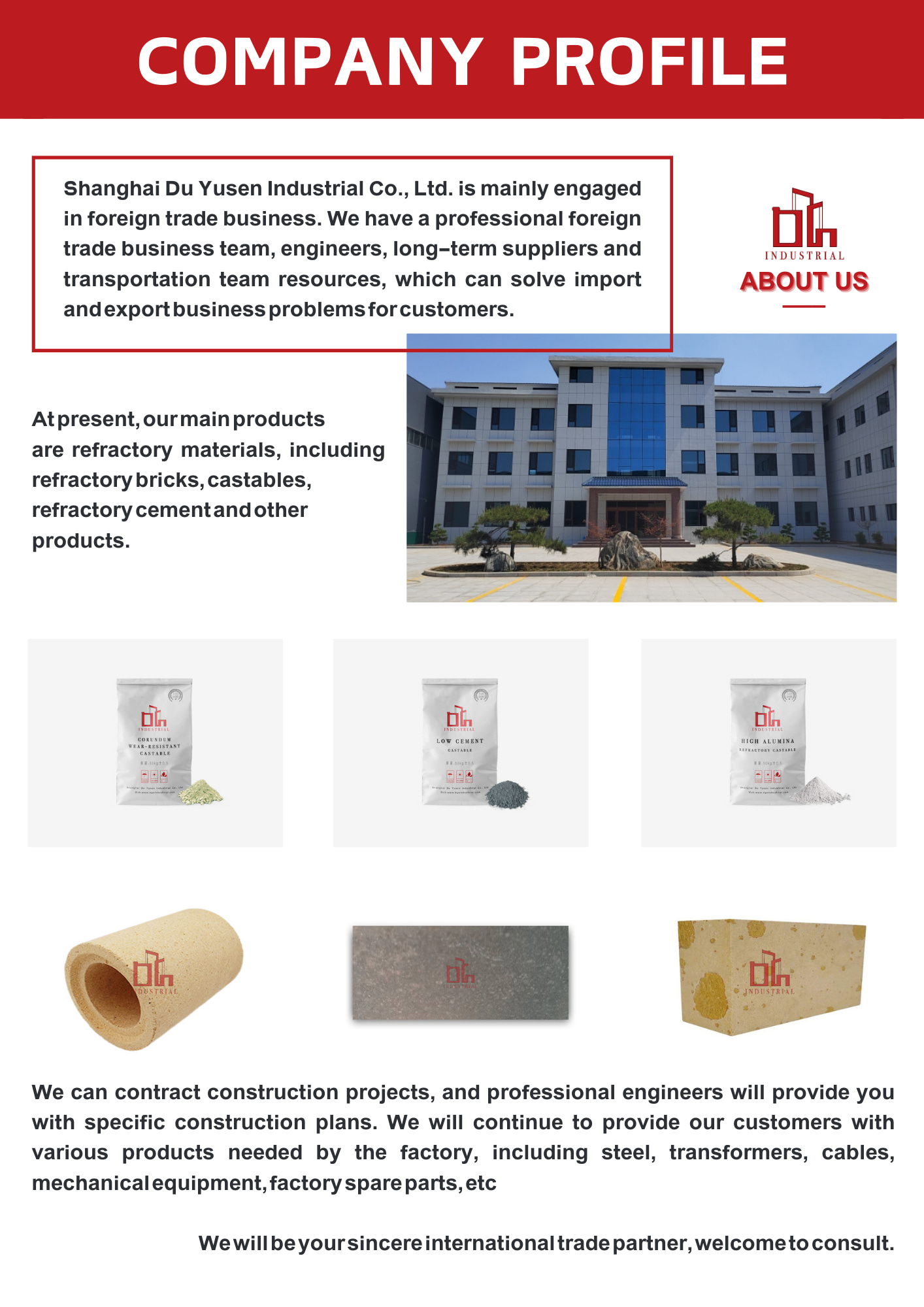

High alumina anchoring bricks, also known as anchor bricks or anchor blocks, are refractory bricks specifically designed for anchoring and securing the lining of industrial furnaces, kilns, and other high-temperature equipment. They play a crucial role in maintaining the integrity and stability of the refractory lining by providing mechanical support and resisting the forces of thermal expansion and contraction.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

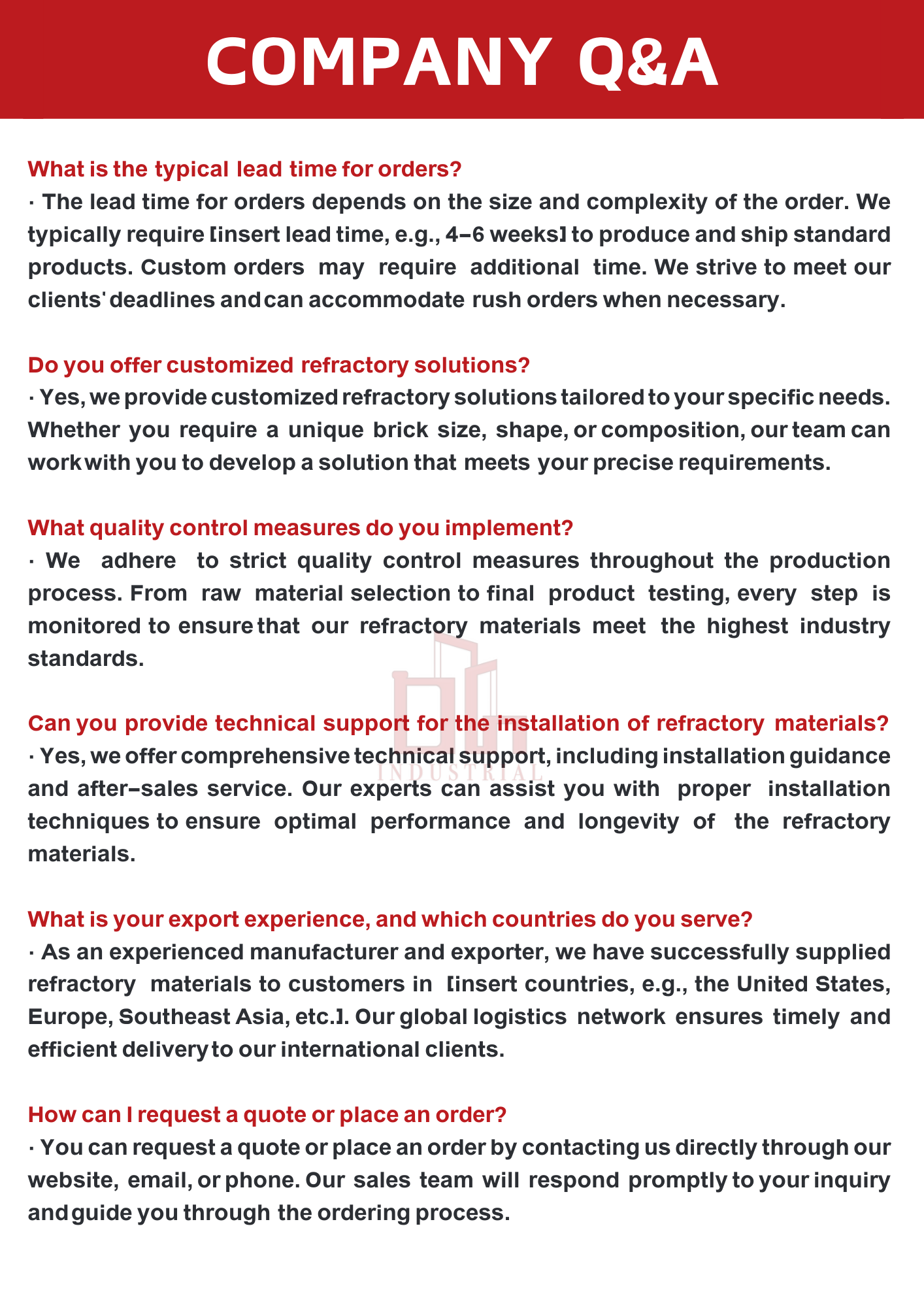

| Item | Grade | ||

| DYSHAAB-55 | DYSHAAB-65 | DYSHAAB-75 | |

| Al2O3, %, ≥ | 55 | 65 | 75 |

| CaO, % ≤ | 2 | 2 | 2 |

| Cold Crushing Strength, MPa, ≥ | 50 | 50 | 55 |

| Tensile Strength, MPa, ≥ | 4 | 4.1 | 4.2 |

| Refractoriness under load 0.2MPa, °C, ≥ | 1450 | 1500 | 1520 |

| Apparent Porosity, %, ≤ | 22(24) | 23(24) | 21(23) |

| Bulk Density, g/cm3 | 2.3 | 2.35-2.4 | 2.5-2.6 |

| Heating Permanent Linear Change (1500°Cx2h), % | -0.4~+0.2 | -0.3~+0.2 | -0.3~+0.2 |

Key features and characteristics:

High Alumina Content: These bricks are typically composed of high-purity alumina aggregates, with alumina content ranging from 45% to 80% or even higher. The high alumina content contributes to their excellent refractoriness and resistance to high temperatures.

Good Mechanical Strength: High alumina anchoring bricks have high compressive strength and mechanical stability, allowing them to withstand the load and stresses exerted on the refractory lining. Their strength is crucial for securely holding the lining in place.

Various Shapes and Sizes: Anchor bricks are available in a variety of shapes and sizes to accommodate different installation requirements and lining configurations. Common shapes include rectangular, square, and trapezoidal bricks, as well as special shapes with notches, grooves, or holes for anchor placement.

Anchor Placement: The bricks are designed with built-in features such as holes, slots, or channels to accommodate anchors or metal fasteners. Anchors are inserted into these features and extend into the backup insulation or structure behind the lining, providing a secure attachment point for the brickwork.

Thermal Shock Resistance: High alumina anchoring bricks exhibit good resistance to thermal shock, allowing them to withstand rapid temperature changes without cracking or failure. This property is essential in applications where the equipment goes through frequent heating and cooling cycles.

Chemical Resistance: These bricks are resistant to chemical attack from various industrial atmospheres and process conditions, making them suitable for applications in corrosive environments.

Aplication:

In summary, high alumina anchoring bricks provide mechanical support, stability, and resistance to thermal expansion in refractory linings of high-temperature equipment. They ensure the longevity and performance of the lining by securely anchoring it in place, even under high temperatures and harsh operating conditions.

Tags :