Low cement castable is a type of refractory castable material that contains a minimal amount of cement binder compared to conventional castables. Typically, low cement castables have a cement content of less than 8% by weight. This low cement content results in a higher refractoriness and better resistance to thermal shocks and chemical attacks.

Payment :

In AdvanceProduct Origin :

ChinaShipping Port :

Shanghai PortLead Time :

15 Working daysProduct parameters:

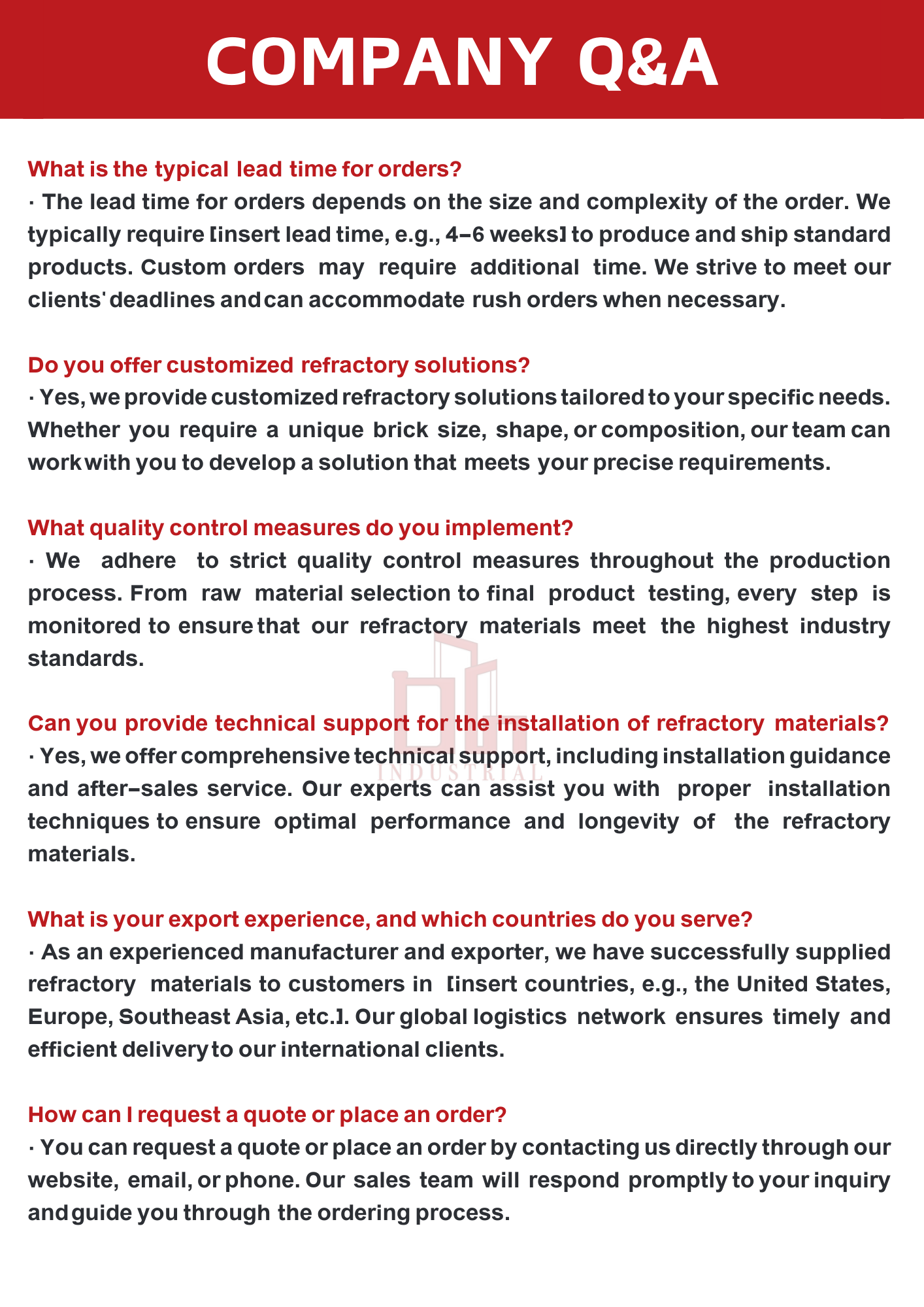

| Low Cement Castable | Corundum | Alumina | Alumina | Alumina | Alumina | Clay | |

| KR-90 | KR-80 | KR-70 | KR-60 | KR-50 | KR-40 | ||

| Chemical composition, % | Al₂O₃ ≥ | 90 | 80 | 70 | 60 | 50 | 40 |

| CaO ≥ | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Bulk density, g/cm3 ≥ | 110℃×24h | 2.95 | 2.75 | 2.6 | 2.5 | 2.4 | 2.3 |

| 1500℃×3h | 2.9 | 2.7 | 2.6 | 2.4 | 2.4 | 2.3 | |

| Compressive strength, MPa ≥ | 110℃×24h | 60 | 45 | 45 | 40 | 40 | 40 |

| 1500℃×3h | 80 | 75 | 70 | 60 | 60 | 60 | |

| Breaking strength, MPa ≥ | 110℃×24h | 8 | 7 | 6 | 6 | 6 | 6 |

| 1500℃×3h | 10 | 10 | 10 | 8 | 8 | 8 | |

| Linear Change PLC, % ≤ | 110℃×24h | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 | -0.1 |

| 1500℃×3h | -0.5 | -0.5 | -0.5 | -0.5 | -0.5 | -0.2 | |

| Max. service temperature, ℃ | 1700 | 1600 | 1500 | 1450 | 1400 | 1350 | - |

low cement castable refractory is composed of high-quality refractory aggregates, fine powders, and a low amount of cement binder. The aggregates can include materials such as high alumina, magnesia, or silicon carbide, which provide the main refractory properties of the castable. The fine powders, known as fillers, are added to improve the workability and densification of the castable mix. The cement binder, in small quantities, acts as a bonding agent that helps to hold the castable particles together.

The low cement content in these castables offers several advantages over conventional castables:

Improved refractoriness: The reduced amount of cement binder allows for higher refractory aggregate content, leading to a higher melting point and improved thermal stability.

Higher strength and density: The low cement content promotes better particle packing and increased density, resulting in improved mechanical strength and resistance to erosion and abrasion.

Enhanced thermal shock resistance: The lower cement content reduces the formation of low-melting phases during thermal cycling, enhancing the castable's ability to withstand rapid temperature changes without significant damage.

Reduced porosity: Low cement castables have lower porosity compared to conventional castables, which improves their resistance to chemical attacks from gases, slags, and molten metals.

Low cement castables find applications in a wide range of high-temperature industries, such as steelmaking, cement production, petrochemical refining, and power generation. They are used for lining various types of furnaces, kilns, ladles, and other equipment that are exposed to severe thermal and chemical conditions.

It's worth noting that the specific composition and properties of low cement castables can vary depending on the intended application and the specific requirements of the installation. Therefore, it's important to consult with the manufacturer or a refractory expert to select the appropriate low cement castable for a particular application.

The way castables are used also determines the quality of the project. Our company has a professional engineering team, welcome to consult.

Tags :