Applications of T2 Brass in the Automotive Industry

Sep 26, 2025In the dynamic automotive sector of 2025, T2 brass—also known as C11000 or oxygen-free high-conductivity copper—stands out as a premium material for its exceptional purity and performance. With a copper content exceeding 99.9%, T2 brass offers superior electrical and thermal conductivity, corrosion resistance, and formability, making it ideal for demanding vehicle components. As electric vehicles (EVs) and advanced driver-assistance systems (ADAS) dominate the market, T2 brass's role in efficient wiring, cooling, and connectors is more critical than ever. Globally, copper demand in autos is projected to surge, with EVs requiring up to 83 kg per vehicle compared to 23 kg in traditional cars, fueling a market growth from USD 241.88 billion in 2024 to USD 248.17 billion this year.

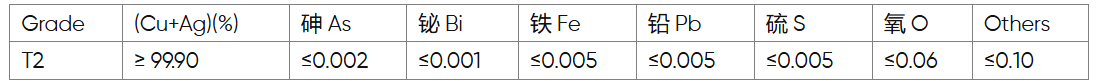

T2 brass is essentially high-purity copper with minimal oxygen (less than 0.001%) and trace impurities, ensuring it remains free from defects like hydrogen embrittlement during welding. Its composition adheres to GB/T 5231-2012 standards, with density at 8.9 g/cm³ and a melting point of 1083°C. Key properties include electrical conductivity near 100% IACS, thermal conductivity of 385 W/m·K, and excellent ductility for cold working. These attributes make T2 brass resistant to corrosion in humid or saline environments, vital for automotive longevity. Unlike alloyed brasses, its low zinc content enhances machinability without sacrificing strength, allowing precise fabrication for intricate parts.

T2 brass's versatility shines in automotive engineering. Primarily, it's used in radiator tanks and cores for its heat dissipation prowess, outperforming aluminum in high-pressure scenarios—essential for heavy-duty trucks and EVs where thermal management prevents battery overheating. In electrical systems, T2 forms busbars, terminals, and wiring harnesses, supporting high-current flows in EV motors and ADAS sensors with minimal energy loss.

Fuel and brake lines benefit from its corrosion resistance against fuels and brake fluids, while connectors and fittings in transmissions ensure reliable seals. Emerging uses include EV charging ports and inductive charging coils, where T2's conductivity boosts efficiency. In luxury vehicles, its aesthetic gold-like finish adorns decorative trims, blending form and function.

As of September 2025, the automotive copper market is booming amid electrification trends. Global demand is expected to reach 28 million metric tons annually, with a 6.5% CAGR through 2030, driven by EV sales projected at 17 million units this year. Asia-Pacific leads with 55% share, as China's "Made in China 2025" initiative ramps up domestic production, though supply deficits loom due to mining disruptions in Chile. Prices hover at USD 4.54 per pound, with forecasts for H2 bullish at USD 4.70, influenced by U.S. CHIPS Act subsidies and EU green mandates.

Sustainability is key: recycled T2 brass reduces carbon footprints by 80%, aligning with circular economy goals. Challenges include price volatility from geopolitical tensions, but innovations like CuproBraze radiators extend lifespan to 140,000 miles, cutting waste. For procurement, Dysen Industrial offers top-grade T2 brass solutions tailored for automotive needs.

In summary, T2 brass powers the automotive future, enabling safer, greener vehicles in 2025's electrified landscape. Its blend of performance and recyclability positions it as indispensable for innovation.

Tags :